Functional Container Performance Testing

Rigorous testing to meet USP<671>, USP<661.2>, and USP<643> standards—because product safety starts with reliable packaging.

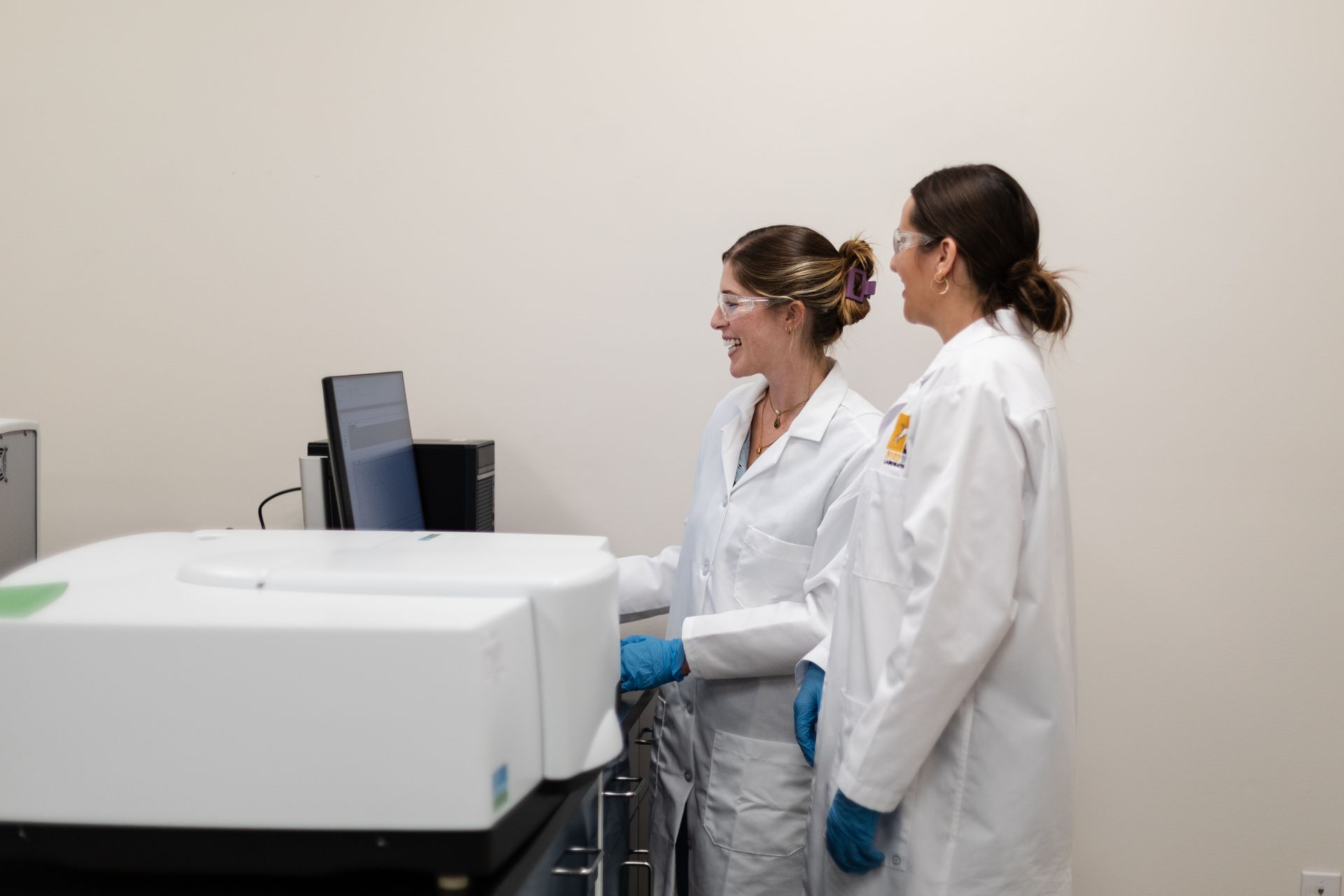

Advanced testing solutions for packaging integrity

Ensure packaging integrity with Bird Dog Laboratories and our container performance testing services. We are ISO 17025-accredited to perform USP<671>, USP<661.2>, and USP<643> testing for the functional properties of packaging systems used for pharmaceuticals, dietary supplements, and consumer products.

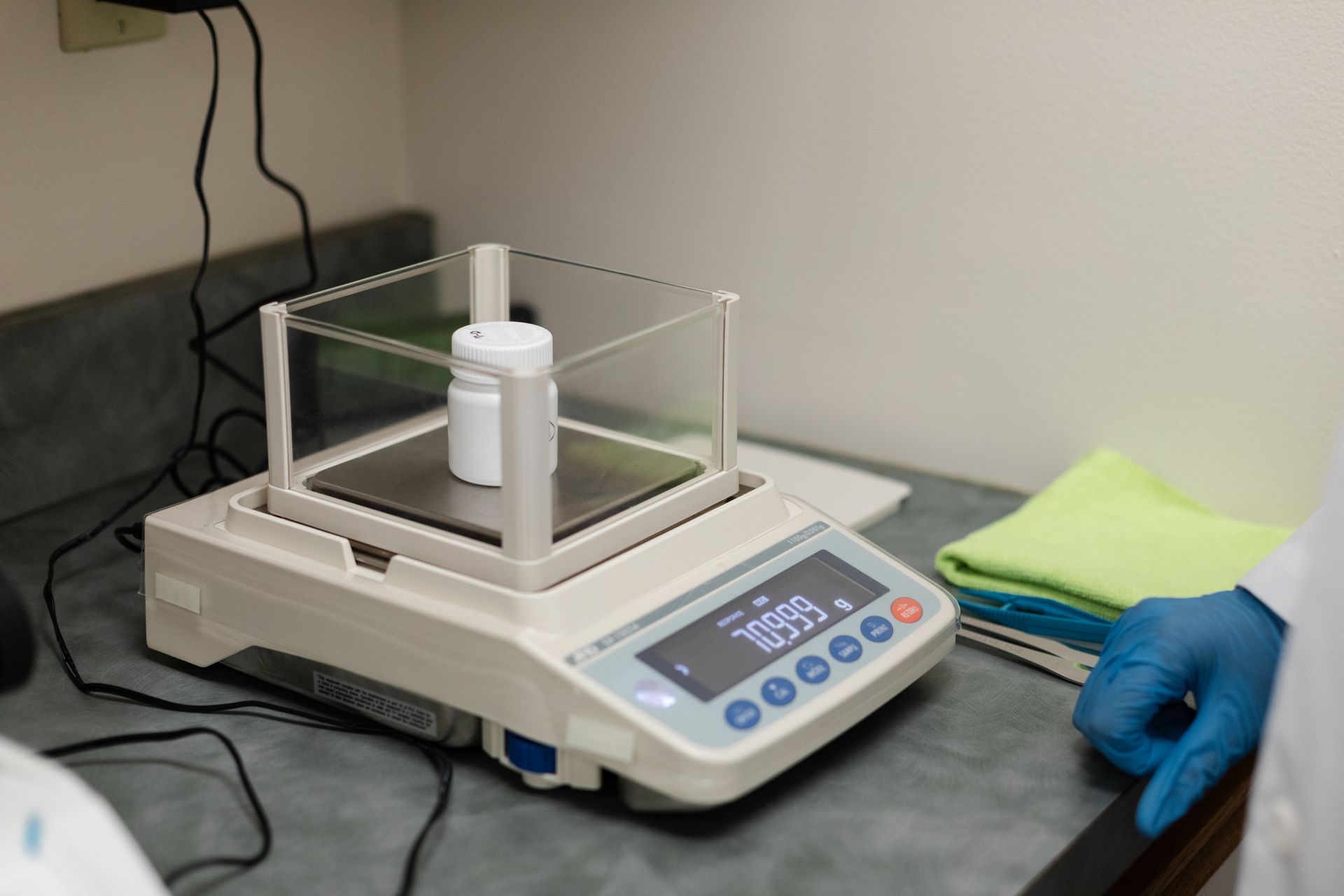

Physicochemical Testing

Physicochemical testing analyzes the physical and chemical properties of a material to ensure it meets quality, safety, and regulatory standards, as well as its compatibility with the drug product.

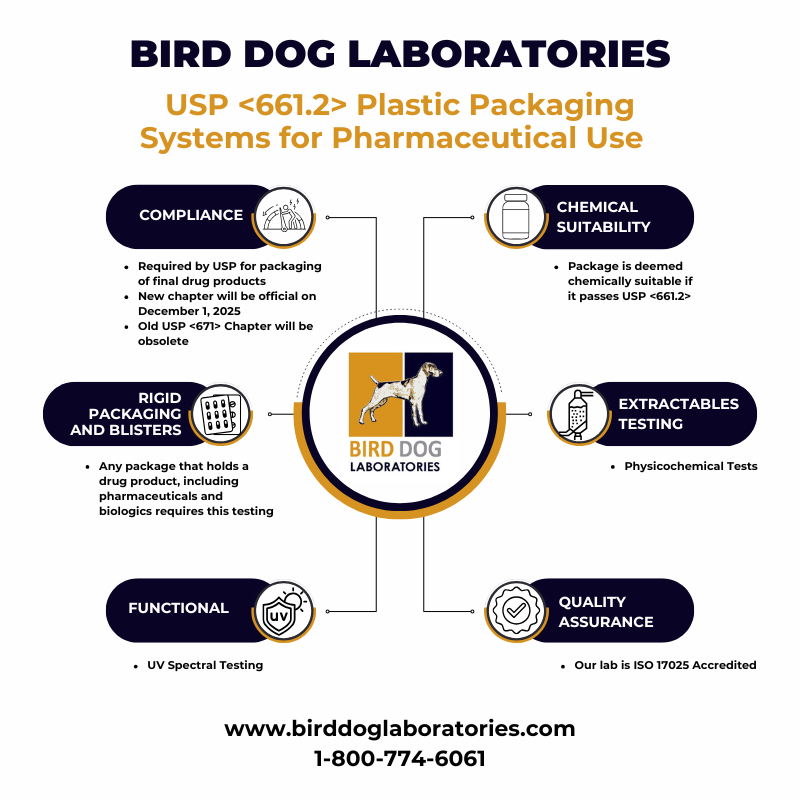

USP <661.2> Plastic Packaging Systems for Pharmaceutical Use

This standard ensures that packaging systems don’t interact with, contaminate, or compromise the drug they contain.

Functional Testing

Functional testing analyzes the form, fit, and function of the entire package ensuring all aspects perform as intended.

USP <661.2> Plastic Packaging Systems for Pharmaceutical Use

This testing ensures a product's packaging component or system is deemed chemically suited for its intended use. This applies specifically to plastic packaging components and systems used for packaging final drug products.

Total Organic Carbon (TOC) - USP<643>

USP <643> is a chapter in the United States Pharmacopeia that provides the official method for measuring Total Organic Carbon (TOC) in pharmaceutical water.

TOTAL ORGANIC CARBON (TOC) TESTING

Total Organic Testing ensures the water’s purity by quantifying organic impurities that could impact pharmaceutical product quality and patient safety.

USP <671> Permeation Testing

We test the functional properties of packaging systems used for solid oral dosage forms (SODFs) and liquid oral dosage forms (LODFs). The methods used determine the moisture vapor transmission rate (MVTR), i.e., water vapor permeation rate, for plastic packaging systems for manufacturers, packagers, and repackers.

The methods also allow pharmacists and institutional repackagers to select appropriate containers to repackage SODFs and LODFs.

Accredited in all Methods of USP <671>

Method 1: Barrier protection

Method 1, known as barrier protection, assesses plastic containers and closures for solid oral dosage forms. It involves testing 15 containers and closures under conditions mimicking manufacture or storage. Anhydrous calcium chloride desiccant is used, and the test lasts 35 days at 40°C/75% RH, with weighings at specified intervals. Results are reported as average mg/day/container.

Method 2: High-barrier blister pack

Method 2 evaluates high or ultra-high barrier blister cards for SODF. It tests 10 Test Units, each with at least 10 cavities, using USP Reference Standard Desiccants. The test duration is 35 days at 40°C/75% RH. Results are reported as average mg/day/cavity.

Method 3: Low-barrier blister pack

Method 3, akin to Methods 1 and 2, assesses low-barrier blister cards for SODF. It tests 10 Test Units, each with at least 10 cavities, using USP Reference Standard Desiccants. The test duration is 2 days at 40°C/75% RH. Results are reported as average mg/day/cavity.

Method 4: Moisture egress

Method 4 is for blister cards of various barrier types, focusing on moisture egress. It tests 10 Test Units, each with at least 10 cavities, using water instead of desiccant. The test duration is 35 days at 40°C/25% RH. Results are reported as average mg/day/cavity.

Method 5: Multi-unit plastic packaging without induction seals

The Method 5 classification test is for multiple-unit SODF plastic packages without an induction seal. It uses 10 containers and 2 controls and desiccant. The test duration is 14 days at 23°C/75% RH, with results in mg/day/liter.

Method 6: Multi-unit plastic packaging with induction seals

Method 6 classifies multiple-unit SODF plastic packages with an impervious seal, like induction seals. It uses 10 containers and 2 controls and desiccant, with the same test duration and result format as Method 5.

Method 7: Solid oral dosage form

Method 7 is a classification test for single-unit SODF containers. This method uses molecular sieve desiccants and assesses blister cards for moisture vapor transmission. The classification is A, B, C, or D based on performance.

Method 8: Liquid oral dosage form

Method 8 is a classification test for multiple unit liquid oral dosage form (LODF) containers. It uses 10 containers and 2 controls and water to assess moisture egress. Results are expressed as a percentage of weight loss, and containers are classified as “tight” if they meet specifications.

MVTR (Moisture Vapor Transmission Rate) & WVP (Water Vapor Permeation)

MVTR (Moisture Vapor Transmission Rate) and WVP (Water Vapor Permeation) both measure the rate at which water vapor passes through a material, ensuring product integrity and longevity. The key distinction lies in their application—MVTR is used for solid materials, while WVP is required for liquid products. Since moisture exposure can degrade products, reduce shelf life, and impact safety, these tests are essential for maintaining quality and performance.

Torque Studies

Torque Studies measure the force needed to apply or remove a closure during the initial performance, ensuring proper seal strength.

Package Life Cycling

Package Life Cycling testing helps manufacturers predict packaging performance over time, ensuring quality, safety, and reliability from production to end use.

Back-Ratchet Package Testing

Back-Ratchet Package Testing evaluates the effectiveness and durability of child-resistant and tamper-evident closures by measuring the functionality of their ratcheting mechanisms.

Torque Degradation Testing

Torque Degradation Testing measures how closure torque changes over time under various conditions and detects issues like loosening, over-tightening, or material degradation.

Child-Resistant Package Testing — Bird Dog Marketing Group

We have completed USP <671> testing on a small scale for a few of our clients for 20+ years through

Bird Dog Marketing Group. Bird Dog Laboratories was created in response to more of our clients requesting additional lab testing because they appreciated our reliability, expertise, and responsiveness. Bird Dog Marketing Group is an international industry leader in the provision of Child Resistant (CR) and Senior Adult Use Effectiveness (SAUE) protocols. For over 55 years, we have been providing comprehensive research and testing services and have a track record of success in safety and child resistant package testing.

Future Testing Capabilities

We continuously grow and evolve to meet our customers' needs, ensuring our lab stays at the forefront of testing innovation. If you require a test not listed on our site, don’t hesitate to reach out. We're eager to learn about your specific needs and explore how we can collaborate to support your goals.

ISTA Testing (International Safe Transit Association)

ISTA Testing is a series of packaging performance tests that evaluates how well a package can withstand shipping, handling, and transportation and ensures it is free from damage.

OTR Testing (Oxygen Transmission Rate)

OTR Testing measures how much oxygen passes through a material over a specific period and ensures that oxygen-sensitive products stay stable and effective throughout their shelf life.

Proven testing methodologies

Precision testing, designed for compliance

As container performance standards continuously evolve, staying compliant is essential for safety and regulatory adherence. Our testing delivers accuracy and reliable results every time.

Partner with Bird Dog Laboratories for unmatched precision & expertise

With a commitment to excellence, our USP<671>, USP<661.2>, and USP<643> testing services aim to:

- Ensure product integrity

- Protect patients

- Ensure regulatory compliance

- Promote innovation and trust

Decades of earned expertise in USP <671> testing

We understand the importance of reliability and industry expertise and have worked hard over the years to establish ourselves as leaders in container performance testing for both pharmaceutical and consumer applications.

Tailored solutions for your business

Whatever your needs, we prioritize open communication and collaboration throughout the process, giving you a streamlined experience. No matter the project, we provide customized, reliable, and results-driven services, giving you peace of mind and time to focus on other aspects of your business.

Ready to test your container performance?

Exceed standards with USP<671>, USP<661.2>, AND USP<643>

testing for flawless packaging performance.

Trust us at Bird Dog Laboratories for all of your pharmaceutical and consumer container performance testing needs. Rely on our comprehensive testing solutions so your packaging meets regulatory standards, product safety requirements, and performance expectations.

Our team is here to deliver accurate, reliable, and industry-leading results you can count on.

Contact Us

Let’s Get Started.

Ensuring product quality through functional testing of packaging systems.